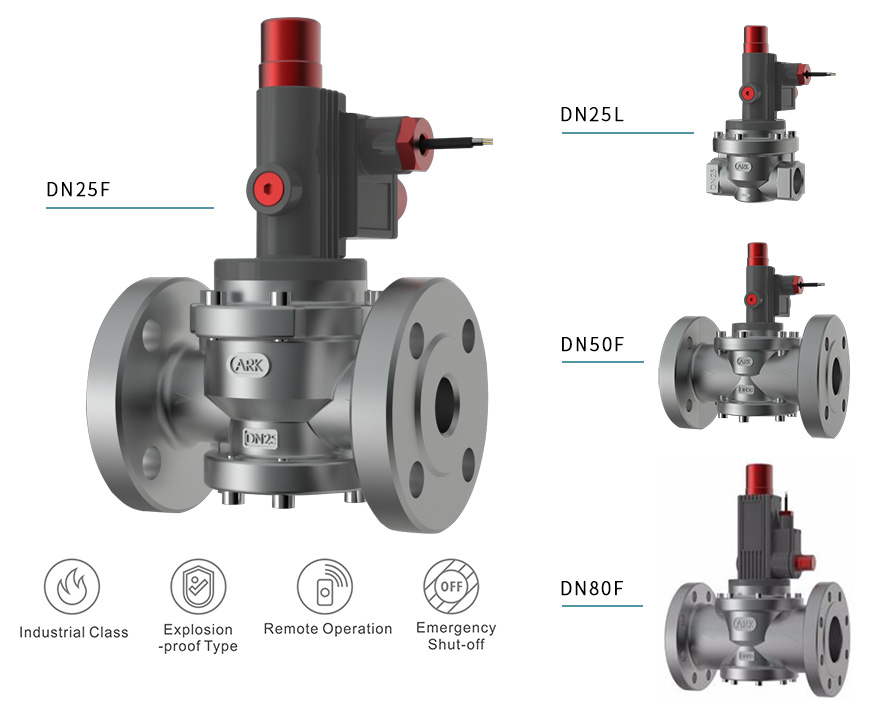

Industrial Class Explosion- Proof Emergency Gas Shut-off Valve

Industrial Class Explosion- proof Emergency Gas Shut-off Valve

YK02- DN25~DN300

The YK02 series YK02-DN25~DN300 electromagnetic emergency shut-off valve for gas (hereinafter referred to as valve) produced by our company is a safety emergency shut-off device for gas pipelines. It can be connected with a gas leakage alarm system or to fire protection and other intelligent control alarm terminal modules, and the others. When various gas unsafe conditions are detected (such as leakage, abnormal pressure or flux, earthquakes, fire disaster, power cut or insecurity of gas usage, it can be linked to the valve to quickly and safely shut off gas in the pipeline, and effectively reduce the accident risk.

The electro-magnetic emergency shut-off valve for gas is designed according to the all standard requirements from GB3836.9-2014 (Explosive environment part 9: Equipment protected by casting type "m") and GB3836.1-2010 "Explosive environment Part 1: General requirements of equipment" . The structure of the electromagnetic emergency shut-off valve for gas seals the internal parts of the valve, the internal parts of the actuator and the parts may generated electric sparks or heat during the operation of the cable into the internal of compound, thus electromagnetic emergency shut-off valve for gas can be worked safely in explosive environment.

The design of valve uses a double structure of a mechanical lock and a permanent magnet lock. When the valve is in an state switching on, the mechanical lock structure is used to overcome the spring force to lock the spring in a state of compression; the permanent magnet lock structure is used to fix the trigger structure of the mechanical lock in the open position. When the valve receives the signal of switching off valve,the discharge module will output a pulse current to the electromagnetic coil in the permanent magnet lock structure, and the instantaneous magnetic force generated by the pulse current will unlock the permanent magnet lock structure, and the trigger structure is moved to the closed position; When the trigger structure is in the closed position, the mechanical lock is unlocked and the valve is closed by the spring force.

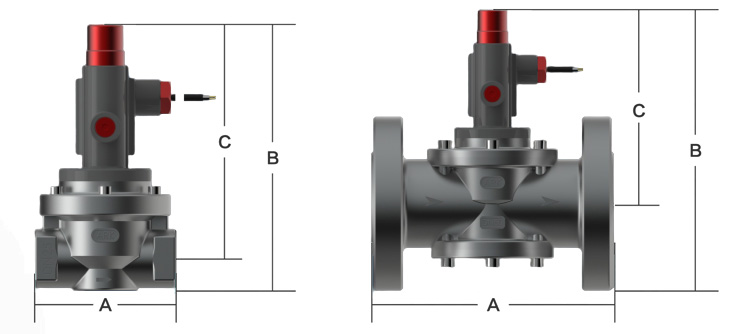

Dimension And Specification:

Model | Body material | Caliber | A(mm) | B(mm) | C(mm) |

YK02-DN25/(0.1/0.2/0.4)-L-K | Cast Aluminium Alloy, Steel(WCB) | G1” | 110 | 207 | 182 |

YK02-DN25/(0.1/0.2/0.4)-F-K | Cast Aluminium Alloy, Steel(WCB) | DN25 | 160 | 236 | 179 |

YK02-DN32/(0.1/0.2/0.4)-L-K | Cast Aluminium Alloy, Steel(WCB) | G1 1/4” | 120 | 212 | 181 |

YK02-DN32/(0.1/0.2/0.4)-F-K | Cast Aluminium Alloy, Steel(WCB) | DN32 | 180 | 247 | 177 |

YK02-DN40/(0.1/0.2/0.4)-L-K | Cast Aluminium Alloy, Steel(WCB) | G1 1/2” | 136 | 216 | 181 |

YK02-DN40/(0.1/0.2/0.4)-F-K | Cast Aluminium Alloy, Steel(WCB) | DN40 | 200 | 257 | 182 |

YK02-DN50/(0.1/0.2/0.4)-L-K | Cast Aluminium Alloy, Steel(WCB) | G2” | 140 | 223 | 183 |

YK02-DN50/(0.1/0.2/0.4)-F-K | Cast Aluminium Alloy, Steel(WCB) | DN50 | 230 | 267 | 184 |

YK02-DN65/(0.1/0.2/0.4)-F-K | Cast Aluminium Alloy, Steel(WCB) | DN65 | 290 | 282 | 189 |

YK02-DN80/(0.1/0.2/0.4)-F-K | Cast Aluminium Alloy, Steel(WCB) | DN80 | 310 | 410 | 310 |

YK02-DN100/(0.1/0.2/0.4)-F-K | Cast Aluminium Alloy, Steel(WCB) | DN100 | 350 | 427 | 317 |

YK02-DN125/(0.1/0.2/0.4)-F-K | Cast Steel(WCB) | DN125 | 400 | 442 | 322 |

YK02-DN150/(0.1/0.2/0.4)-F-K | Cast Steel(WCB) | DN150 | 480 | 480 | 340 |

YK02-DN200/(0.1/0.2/0.4)-F-K | Cast Steel(WCB) | DN200 | 495 | 532 | 362 |

YK02-DN250/(0.1/0.2/0.4)-F-K | Cast Steel(WCB) | DN250 | 622 | 582 | 392 |

YK02-DN300/(0.1/0.2/0.4)-F-K | Cast Steel(WCB) | DN300 | 698 | 810 | 430 |

Industrial Class Explosion-proof Emergency Gas Shut-off Valve

YK02- DN25~DN300

Parameter Of Product:

Characteristics Of Project | Characteristic Of Parameter (Description Of Characteristic) |

Sealing Material | Special Rubber NBR, FKM Rubber |

Material Of Valve Body | ZL101A Cast Aluminium Alloy, Carbon Steel(WCB) |

Way Of Switching Off The Valve | DC pulse drive or manual operation |

Capacitance C Value Of Alarm | 1000~4700μf/50V Withstand voltage; Actuation time of switching off valve:≤1s |

Inductance | Coil body:3.1~3.3mH/ State of switching on valve:5.9~6.1mH/ State of switching off valve:4.6~4.9mH |

Action Reliability | More than 3000 times for switching on/off |

Service Life | Ten years (Conform with CJ/T146-2011 ) |

Standard To Be Satisfied | (Enterprise Standard) QB/0001-2018 GB3836.1-2010,GB3836.9-2014,CJ/T 394-2018 |

Working Pressure | 25≤DN≤300:0.1-0.6MPa |

Scope Of Environment And Temperature | -10C ~ +50C |

Explosion-proof Mark | Ex mb II T6 Gb |

Protection Class | IP54(Need to be covered with protecting cover)The position of the outlet port is connected with the steel pipe or the sleeve pipe to form a sealed environment. |

Way Of Connection | Thread, Flange |

Length Of Cable | 0.45m(Take the valve by oneself) |